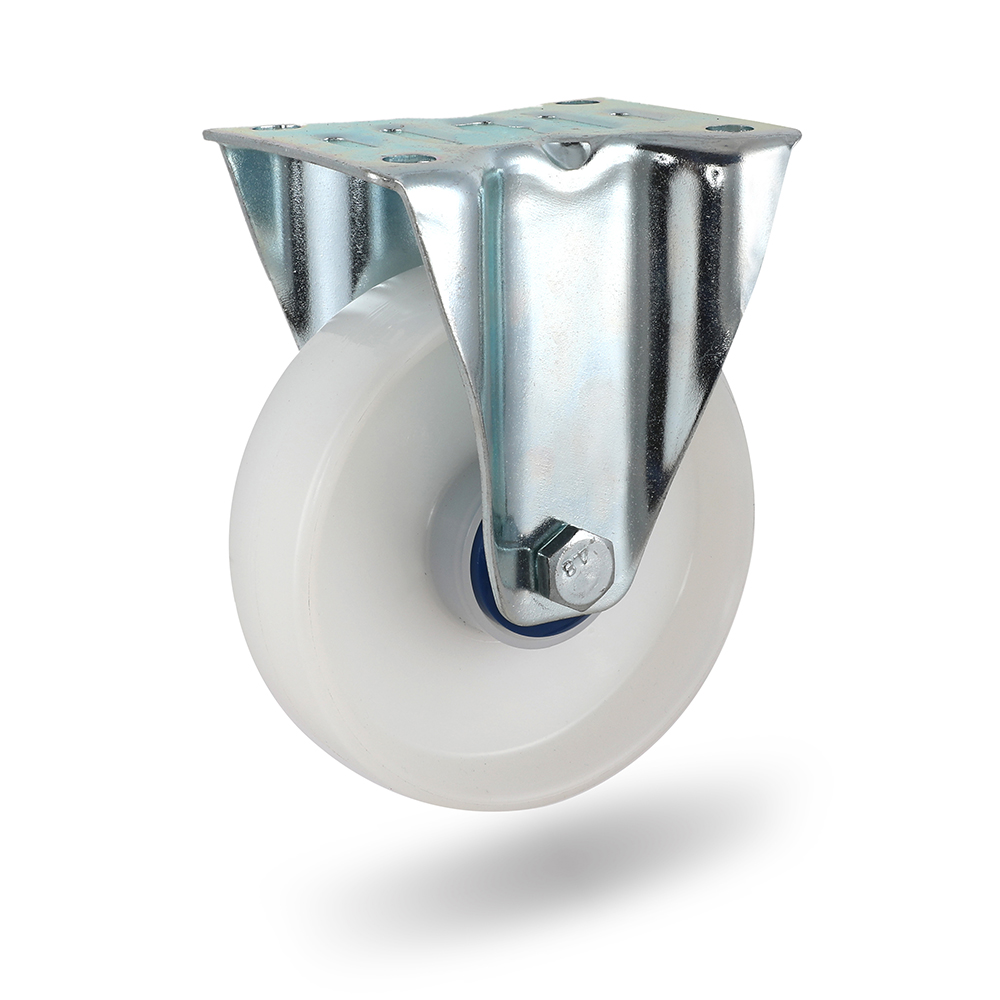

125 hli (Polypropylene) PP Log, Ruaj Khoov, Nruab Nrab Ua Haujlwm Castors, European stamping industrial bracket, Zinc (galvanized) nto

Qws: R series

• Kev kho qhov chaw ntawm cov hlau thiab zinc uas nias

• Lub Rooj Sib Txuas Ruaj Kho

• Kev txhawb nqa castor ruaj khov tuaj yeem kho rau hauv av lossis lwm lub dav hlau, zam kev siv cov khoom siv ntawm kev co thiab co, nrog kev ruaj khov zoo thiab kev nyab xeeb.

Log:

• Lub log log: Lub log PP (Polypropylene) dawb, tsis muaj cim, tsis muaj xim

• Lub log ntug: txhaj tshuaj molding, Central precision pob bearing.

Lwm yam ntxwv:

• Kev tiv thaiv ib puag ncig

• hnav tsis kam

• Kev Tiv Thaiv Kev Poob Siab

| Log Ø (D) | 125 hli | |

| Qhov Dav Ntawm Lub Log | 36 hli | |

| Muaj Peev Xwm Thauj Khoom | 150 hli | |

| Tag Nrho Qhov Siab (H) | 155 hli | |

| Qhov Loj ntawm Phaj | 105 * 80 hli | |

| Qhov Chaw Sib Nrug Ntawm Qhov Rooj | 80 * 60 hli | |

| Qhov loj ntawm lub qhov ntsia hlau Ø | 11 * 9 hli | |

| Kev Sib Tshuam (F) | 38 hli | |

| Hom kabmob | Ib lub pob bearing | |

| Tsis cim | × | |

| Tsis muaj xim | × |

Cov khoom tsis

|

|

|

|

|

|

|

|

|

|  |

| Txoj kab uas hla ntawm lub log | Thauj khoom | Qag | Qhwv | Thauj khoom | Sab saum toj-phaj sab nraud loj | Qhov Chaw Sib Nrug Ntawm Qhov Rooj | Qhov Loj ntawm Qhov Rooj | Qhib | Tus lej khoom |

| 80 * 36 | 120 | / | 2.5 | 108 | 105 * 80 | 80 * 60 | 11 * 9 | 42 | R1-080R-111 |

| 100 * 36 | 150 | / | 2.5 | 128 | 105 * 80 | 80 * 60 | 11 * 9 | 42 | R1-100R-111 |

| 125 * 36 | 160 | / | 2.5 | 155 | 105 * 80 | 80 * 60 | 11 * 9 | 52 | R1-125R-111 |

| 125 * 40 | 180 | / | 2.5 | 155 | 105 * 80 | 80 * 60 | 11 * 9 | 52 | R1-125R-1112 |

Cov yam ntxwv

1. Kev tiv thaiv cua sov zoo: nws qhov kub thiab txias deformation yog 80-100 ℃.

2. Zoo toughness thiab tshuaj lom neeg kuj.

3. Tsis muaj tshuaj lom thiab tsis muaj ntxhiab, khoom siv zoo rau ib puag ncig, siv tau dua tshiab;

4. Kev tiv thaiv corrosion, acid tsis kam, alkali tsis kam thiab lwm yam ntxwv. Cov organic capacitors xws li acid thiab alkali muaj feem cuam tshuam me ntsis rau nws.

5. Rigid thiab tawv, nrog rau cov yam ntxwv ntawm kev tiv taus qaug zog thiab kev ntxhov siab tawg tsis kam, nws cov kev ua tau zoo tsis cuam tshuam los ntawm cov av noo ib puag ncig; Nws muaj lub neej ntev khoov qaug zog.

6. Ib lub pob bearing muaj suab nrov tsawg thiab siv tau ntev. Qhov zoo yog tias lub suab nrov yuav tsis nce ntxiv tom qab siv ntev, thiab tsis tas siv roj nplua nyeem.

Cov Txheej Txheem Kho Kom Zoo

1. Cov neeg siv khoom muab cov duab kos, uas R & D Management tshuaj xyuas seb peb puas muaj cov khoom zoo sib xws.

2. Cov neeg siv khoom muab cov qauv, peb tshuaj xyuas cov qauv thiab tsim cov qauv.

3. Xav txog cov nqi tsim pwm thiab kev kwv yees.